Reverse logistics can be a daunting task for many organizations. After all, many supply chains are built to send products out – not bring them back in. Online ordering has made great strides, and e-commerce now delivers a user-friendly purchase experience. Now, making returns hassle free for consumers is the last frontier for the supply chain.

In 2018, 10% of retail industry sales were returned, to the tune of $369 billion in merchandise. As a result, many organizations are focused on getting their reverse networks up to speed. Below are three ways companies can rethink the way they handle returns and update their reverse chain:

#1 Identify Why Returns are Happening

Given the high cost of returns, retailers must work to determine the cause of returns and see if the current return policy is encouraging a costly volume of returns. This was the case for L.L. Bean, which ended its lifetime return policy, citing $250 million in losses over the last five years from “abusive” returns.

Are certain products constantly being returned? Are particular items not performing as specified? Analyzing the motive for returns enables businesses to find return patterns, adjust policies, or clarify product details, reducing return frequencies and improving customer satisfaction.

#2 Focus on the Customer Experience

Consumers are more loyal to brands that have a streamlined returns process, and quickly crediting customers’ accounts is essential to retaining their business. This includes looking at cycle time to see how long customers are waiting to be credited for their returned merchandise as well as analyzing dock to stock data for insight into the time it takes for returned products to be made available to consumers again.

To optimize returns, the supply chain must be designed with transparency and visibility in mind. Customers expect tracking for returns and progress reports, which requires an efficient supply chain. With a strategically designed reverse network, retailers can shrink the time frame from when a return is initiated to when a customer is refunded.

Allowing customers to bring back online purchases to physical locations for a more immediate refund has also reduced some of the stress of returns. In 2018, 38% of retailers reported an increase of online returns in-store. This integration between brick-and-mortar stores and e-commerce platforms has eliminated steps for consumers and cut down on the amount of time returned merchandise is in the reverse chain.

#3 Adopt a Holistic View

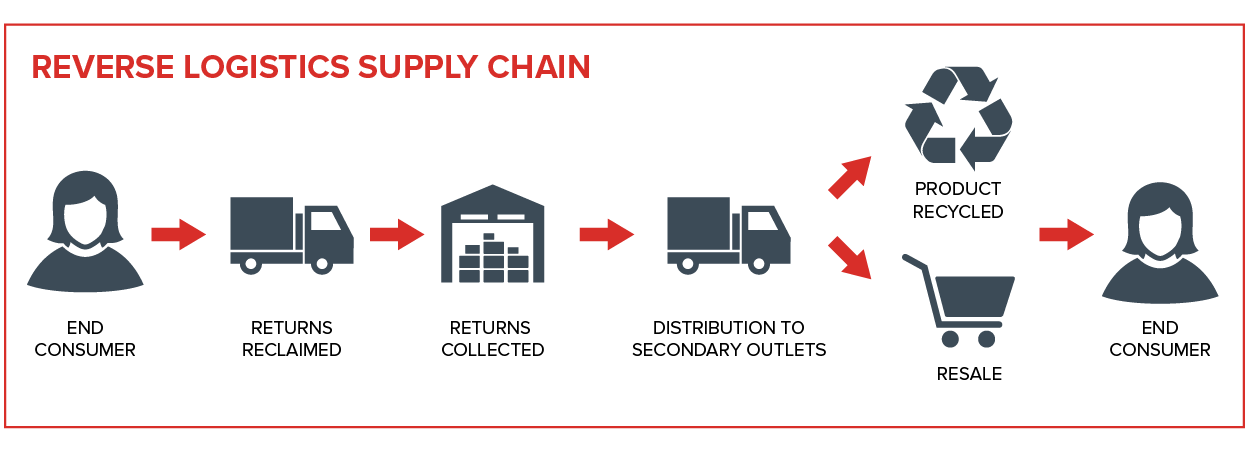

A reverse logistics supply chain cannot be created in a vacuum. Rather, the reverse network must be modeled out as part of an integrated whole. A 3PL has the expertise to help retailers set up the right network and design their supply chain for returns.

Both large and small organizations can practice asset recovery management at some level to obtain the greatest possible return from items. With an eye on the full life cycle of a product from manufacturing to fulfillment to end-of-life, organizations can improve operational efficiency and cut costs.

Rather than falling behind, organizations must adjust to the increase in returns and strategically design the supply chain to efficiently process both forward and reverse networks. An optimized reverse chain can help businesses lower returns volumes, improve the customer experience, and better manage asset recovery. A 3PL partner can assist retailers in creating a data-driven plan that optimizes returns and meets customers expectations.