Supply chain engineers must embrace change to “keep up with the Jones’s.” New technology sweeping our warehouses make things possible that we once only dreamed about: instant printing of physical goods, automated material handling vehicles, advanced robotics and more.

It is only in reflection we get an impressive view of how much supply chain management can evolve in a relatively short time. The last five years, in particular, have brought an enormous amount of changes in our industry. Many of which we embrace––and others, we adapt to work around.

If you’ve felt your company has been on the “treadmill” of supply chain evolution the last few years, just working to keep up, allow us to press ‘pause’ for a moment. Within this blog, I hope to illustrate how and why supply chain management has changed in the last half-decade and how manufacturers and logistics professionals can work together to create customized solutions, make better decisions faster, and prepare for the future.

Major Mergers and Acquisitions

Whether we wrote this post in 2017, 2027, or 2037, mergers and acquisitions would be a topic worthy of discussion. They will always be a part of a capitalistic economy. This year, we are seeing a few key statistics that show companies are expanding into new services by acquiring those companies who are already experts in their desired services:

In 2000, the top 50 3PLs controlled 20% of the industry. In 2012, that number jumped to 50%. Today, the top 50 3PLs control almost 70% of the market. Demonstrating the industry continues to consolidate at an ever increasing rate. More mergers could mean conglomerates could potentially provide a customer with a bigger ensuite of services, but at the same time, merely having a larger ensuite of services, without having competencies in place, could create a potential loss of focus in individual areas.

For your business, this can, unfortunately, mean a potential loss of customization from your 3PL. As more operations add more services, there can be fewer 3PLs who truly customize specific services that your business needs.

On the other hand, we’ve seen many successful customer acquisitions and mergers as a 3PL. If your business has gone through an M&A in the last five years, you understand the need to have a flexible 3PL who can adapt to a more fluid relationship.

Booming eCommerce

eCommerce has existed since the rise of the internet, but in the last five years, it has grown into the market and is becoming more commonplace in our everyday lives. A Pew Research study on eCommerce shopping for consumers shows us 80% of American adults make online purchases, compared to just 22% in 2000.

In terms of delivery to the customer, a 2-day window for delivery is almost old news. As consumers, our expectations are quickly shifting to next-day delivery and even same-day delivery (in some large cities). To take advantage of the rapid delivery provided by companies like Amazon, many small businesses chose to sell their products through Amazon warehouses even though they are giving up more than half of their margin.

Return to Regional Demand

The full cycle of the supply chain is returning to a more regional approach after decades with a slant toward globalization. In recent years, more of China’s production is going towards Chinese demand and less for export. The concept of near-shoring or on-shoring has become more topical since 2012. Protectionistic government policies around the globe will only increase this trend.

However, this does not apply to all types of consumer goods. For instance, mass-produced clothing will likely never be made in the U.S. on a large scale again. But we will likely see a manufacturing renaissance with medium and low-technology, high-end apparel, high-end food and drink, and bags and accessories, for example.

Often, this return to the United States is because technology and design companies fear they can’t have remote leadership while still driving innovation and continuous improvement. To achieve the increased efficiency and reduced costs that come with supply chain innovation, many companies are opting to bring their manufacturing back to America. On another note, many also think near-shoring is required to increase quality and technicality standards.

Increasing Wages

Over the last ten years, the supply chain wage cycle has somewhat remained stagnant. Only within the last two years has the industry started increasing the competitiveness of wages throughout the supply chain.

For instance, Amazon and other eCommerce leaders employ seasonal employees at a very high wage for its highest months of demand. This has increased the competition for quality team members along the supply chain.

As a 3PL, Kenco has embraced this opportunity to provide a better quality of life for our employees at every level. Using the yearly living wage study conducted by MIT as a benchmark, we have increased our employee wages to recognize growth in living costs and build our culture of respect and innovation.

Location, Location, Location (Shortages)

Today, occupancy exceeds build for real estate. 3PLs are moving to more build-to-suit contracts at an ever increasing rate because there are simply no options out there to fit manufacturers’ requests. According to Supply Chain Digest, “With new construction continuing to lag demand, availability rates have fallen every quarter since Q3 2010.”

“Build it, and they will come” lenders fall short in today’s climate. In fact, this demand has created a market where, in the whole Chicagoland area, there may literally be only 1 or 2 buildings suitable for a certain project. According to a mid-2016 statistic, “Industrial vacancy is currently tracking at the lowest level of the past 30 years and is a full 270 bps below the 10-year historical average.”

For your company’s real estate success, it’s essential to make sure you’re working with a 3PL that has strong real estate savvy. In particular, seek in-house brokers and a strong record with build-to-suit knowledge. Create a full real estate partnership, not just lease negotiation or outsourcing.

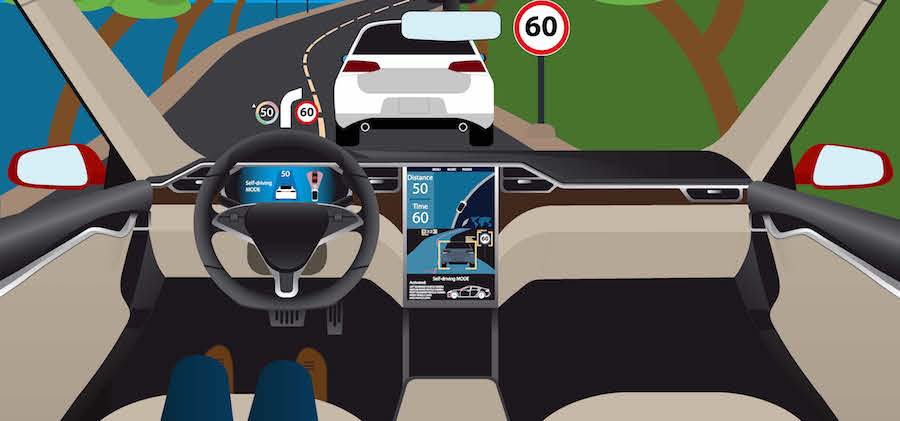

Driverless Transportation is a Reality

The logistics industry now understands the incredible opportunity of driverless transportation in 2017. We have some views from Matt McLelland in a recent CES 2017 review blog post. Five years ago we simply didn’t know where this topic may be progressing. Relatively speaking, driverless transportation innovation happened fast––and as an industry, we’re much further along than we thought we’d be.

This surprising reality is exactly why it’s important to work with a partner who pursues innovations, even when they seem “far-fetched.” You need to look to your 3PL to be your expert knowledge source.

Creative solutions to transportation are so important to reduce costs, such as Walmart’s new tests in employee delivery. Its stores are within 10 minutes of 90% of the population of the United States, and these are just the out-of-the-box transportation innovations that could blow us away when we do this same reflection in 2022.

Read more about how driverless vehicles are changing 3PL transportation strategies around the country in our new eBook, New Supply Chain Technology Best Practices.

Software Shift

Generally speaking, more 3PLs are now moving away from proprietary software and adopting Tier 1 systems. Instead, the true differentiator among providers is business intelligence software. For example, Kenco is sun setting warehouse efficiency and control software in favor of investing in commercially available solutions that are purpose built to support certain business functions which provided Kenco, and our customers, a scalable solution that is continuously benefited from investment.

Many 3PLs are doing the same by becoming experts in the tool, and layering business intelligence on top of the system to create in-depth reports and provide incredible value, making better decisions faster.

Uncertain Infrastructure Improvements

Politically, there seems to be much divide in how and when to improve the infrastructure of the United States. However, the logistics industry––particularly the transportation field––feels rebuilding the infrastructure of the country is essential. This infrastructure allows the logistics industry to provide a supply chain and deliver to end customers. Rebuilding roads and bridges all over the country could take decades, which makes this process potentially overwhelming.

The future of infrastructure improvements is uncertain, and unfortunately, because many of the roads in question are federally controlled, improvements at the state level can only go so far to reduce the stress on networks that span across multiple state lines.

For the past decade, the federal government has put over a dozen “temporary patch” bills in place to finance infrastructure projects across the country. However, we need a holistic, broader strategy to solve the perpetual problems:

“On the surface, funding transportation drop-by-drop might not seem like such a big problem,” said former Transportation Secretary Anthony Foxx in an interview after a passing vote for one such bill in 2015. “But it is, and the facts are unassailable. This era of short-term patches and chronic federal underinvestment has crippled America’s ability to build the transportation system we need.”

Burgeoning Blockchain Technology

One particularly interesting new topic in logistics over the last few years is blockchain technology. A press release issued by IBM explains how this might change supply chain operations:

“Blockchain is a digital technology for recording and verifying transactions. The distributed ledger is a permanent, secure tool that makes it easier to create cost-efficient business networks without requiring a centralized point of control. With distributed ledgers, virtually anything of value can be tracked and traded. For example, it allows securities to be settled in minutes instead of days. It can be used to help companies manage the flow of goods and related payments or enable manufacturers to share production logs with OEMs and regulators to reduce product recalls.”

Many companies are making big investments in blockchain technology, but overall, it has become a topic we’re definitely all talking about it as an industry.

To Sum It All Up

Hopefully, when you look back at the last five years of your supply chain, you see growth and continuous improvement that point you closer to your company goals. The nine concepts above have changed how our products are created, packaged, stored, shipped, and consumed by their end customers––and we’ve enjoyed this reflection as a time to celebrate the strides our logistics industry and our partners have taken.

To dive into the specific, fascinating high-tech that will permeate our warehouses over the next five years, download your copy of our eBook, New Supply Chain Technology Best Practices. In it, you’ll see how drones, robotics, 3-D printing, wearable technology, and more are reshaping the way we work.

{{cta(‘d532c395-c720-4fb4-b345-8b69098155f1’)}}