Have you ever felt as if you are leading from the back of the pack? Without the proper information to make qualified decisions and drive improvements in your business. Do you feel there are gaping holes in your supply chain or between your execution systems? Supply chain visibility could help alleviate some of your pains and drive bottom line benefits.

Supply chain visibility (SCV) is defined as the ability of parts, components, or products in transit to be tracked from the manufacturer to their final destination. Think of it as a control tower at an airport, directing flights for take-off and landing—making all the different airlines work in unison to ensure there are no hiccups along the way.

When you think of all the moving parts and systems involved from product creation to end-delivery, I’m sure you can agree SCV is important for any company.

Here are 3 specific reasons we see it as such an important piece of the logistics puzzle:

Supply Chain Visibility = Business Intelligence

Supply chain visibility enables you to perform “what-if” scenarios. Visualizing these different scenarios can help you predict issues and problems that may arise, and then plan for them and their solutions. That way you can have systems and processes in place that are ready to solve problems as they arise.

One simple “what-if” could be about how your business silos interact. If you have different aspects of your business in silos, and they don’t have the proper communication between them, you are potentially wasting time and money—probably creating questions like, “Are we cutting orders because we don’t have the right hands working together?” Or, “Are shippers and suppliers normally integrated or parceled?”

This is just one example of the worst case scenario you could have: your systems aren’t integrated, and people are making decisions on the information they have available. You could be underutilizing your fleet, or paying a broker an incorrect amount. Your warehouse could be over (or under) staffed which impacts profitability or performance. The list goes on and on when it comes to potential issues caused by lack of system integration.

If systems are not integrated and sharing data, you’ll never gather the business intelligence you need to fix problems, get more efficient and increase profit along the chain.

It Stops The “Hiccups”

Many 3PLs support line-side delivery in manufacturing facilities. Shutting down a production line due to systems and/or operations’ issues could cost your company thousands of dollars in financial penalties for every one-minute of a line shut down—talk about a “hiccup” that affects the bottom line. These kinds of issues can be caused by pieces not working in concert, a.k.a., no supply chain visibility.

Collaboration across systems enables supply chain visibility. For a 3PL, using a YMS with a WMS can help you clear your dock and clean your doors out , and better manage the traffic around the facility. In concert, these two systems help let you know whether or not someone else needs the door and avoid costly dwell times or demurrage fees.

It Unifies Systems

Using a WMS or YMS is standard, but the secret sauce to supply chain visibility is in the data analytics and business intelligence obtained from multiple systems working together. Cross-platforming systems help bridge data gaps and give you better insights into what is happening across your company.

For example, many shippers we work with wants to know the cost per unit. By using better SCV and data analytic tactics, we tie together our WMS with financial accounting and come up with the real-time costs. No waiting and no guessing.

Unifying systems and sharing information between them allow you to access data you may have never known existed. Once you have this data, the information you can pull from it is endless.

How Do You Ensure Supply Chain Visibility?

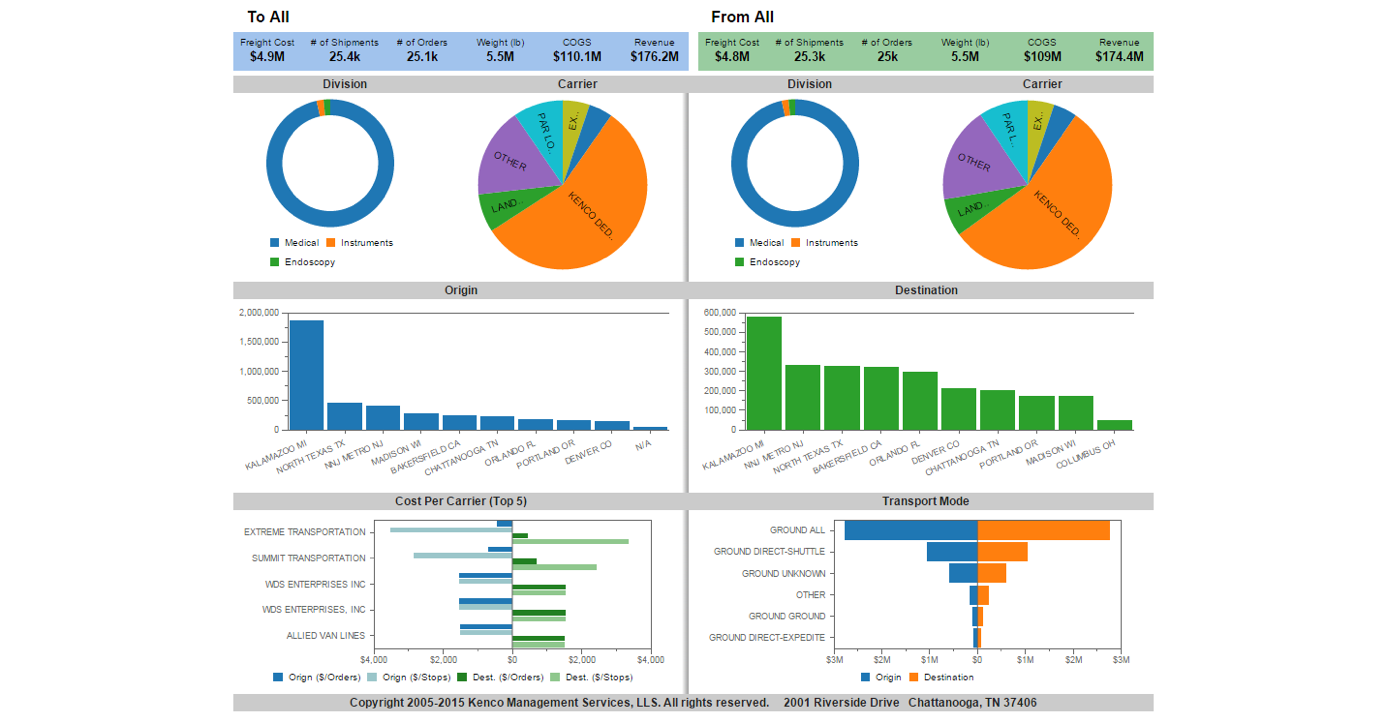

At Kenco, we integrate our Supply Chain Execution (SCE) systems and integrate with our customers through a number of different methods to connect different data sources together so reports and dashboards can be created with real-time data. Our UNIFY system, Kenco’s branded business intelligence system extracts key data from our SCE systems and tie all of the data together. The benefit of having all of your data in one place is you have a global view of the business at the tip of your fingers. The ability to analyze the data through performance reporting and dashboarding aids in the continuous improvement effort we strive for every day. It also gives you the ability to perform predictive and prescriptive analytics.

For example, here is what a freight analysis on our UNIFY system looks like:

Creating a system that talks and shares data from every aspect of your business can seem and sound like a daunting task; but if you are able to look at your current platforms many of these do this and might need some tweaking and thinking outside the box for solutions. The more integrated, the better.

If you’re looking for a 3PL that can help, try our eBook, Selecting & Managing a Third-Party Logistics Provider – Best Practices. The included checklist will help you evaluate your many different provider options once you start searching!