Visual order is the foundation of excellence in our logistics environments. It provides the basis for much of the “management” in a lean management system.

Visual order is the first step in creating a process focused warehouse. This focus makes it easier to see the contrast between expected and actual process performance. Visual order is also the foundation for disciplined action and accountability.

If an associate cannot place a trash can back into the designated location, will they follow standard work for unloading a trailer? It is the indispensable first step of a much more complete process called visual information sharing or visual systems. There are no ands, ifs, or buts about it: You cannot achieve a visual workplace without first putting in the principles and practices of visual order.

In the 1980s, 5S (a narrower version of the approach) received wide attention when companies began to send groups of managers and associates to Japan to tour that countries so-called parlor factories. The name derives from the fact that these plants were white glove clean. No chips, no grease, no grime and in many instances not a speck of dust.

When the visitors asked how this could be the secret they were told it was 5S. 5S means cleanliness and order with a vengeance. This is not putting things in order one week and having them disappear the next week, like a pebble in a pond.

| The Orginal 5Ss | Definition |

| Seri (say-ree) | proper arrangement |

| Seiton (say-ton) | orderliness |

| Seiso (say-so) | cleanliness |

| Seiketsu (say-ket-soo) | cleaned up |

| Shitsuke (she-soo-kay) | disipline |

| American Translation | Definition |

| Sort | remove unnecessary materials and equipment |

| Straighten | make it obvious where things belong |

| Shine | clean eveything, inside and out |

| Standardize | establish policies and procedures to ensure 5S |

| Sustain | training, audit daily activites |

Visual order enables us to remove motion from our processes. To move and add value is called work. To move and not add value is called motion. Motion, then means “moving without working, moving and adding cost.” You may have heard the following catch phrase:

“Activity is not Productivity”

Visual order (5S) impacts motion directly. It eliminates the cause of walking, searching, and other grosser forms of motion. By locating items closer to the point-of-use (POU), we automatically reduce the distance traveled. When the unrelated movements are eliminated and all the tiny interruptions are removed, you can simply do your work. Suddenly it is just you and your work – work that makes sense and the way you have always wanted your work to feel like.

It is difficult to achieve a visual workplace without a roadmap. A visual workplace creates an environment in which compliance is the natural and predictable response.

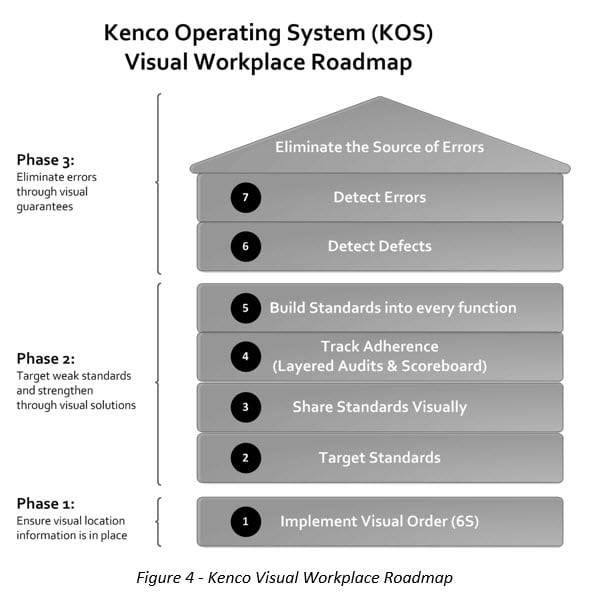

The 8-levels (in figure 4) below are divided into three stages.

- Stage one focuses on implementing visual order.

- Stage two focuses on the adherence to standards that are built into the physical workplace and then scoring the results visually.

- Stage three is all about removing the option of compliance and building in mistake-proofing (only the right thing can happen) into the process.

In other words, the desired outcome is visually guaranteed. So, as you can see the journey to a visual workplace begins and ends with visual systems.