Shortages are touching nearly every corner of the supply chain in 2022, and material handling equipment is no exception. There are many factors behind today’s forklift shortage, including a lack of raw materials to make equipment, a scarcity of microchips that manage key functions in lift trucks, and even regulatory issues—in 2021, for example, Toyota halted the shipping of LPG forklifts in the U.S. pending new certifications from the Environmental Protection Agency (EPA) and California Air Resources Board (CARB).

Despite these shortages, the demand for forklifts remains high; in 2021, forklift orders skyrocketed as compared to the previous two years. This increase combined with the above shortages and pandemic-related delays have elongated lead times for new MHE equipment, leaving many shippers in the lurch.

Additionally, there are well-documented labor shortages impacting productivity and efficiency within the MHE realm. The lack of available, trained forklift operators is pushing many shippers to invest in automated or semi-automated MHE solutions and find ways to make MHE management easier for employees.

In challenging times like these, it’s necessary to lean into innovation. There is an abundance of new automation solutions and technologies on the market to offset the impact of MHE and operator shortages. Below are just six of the many solutions Kenco and our customers are utilizing to drive efficiency and keep operations lean.

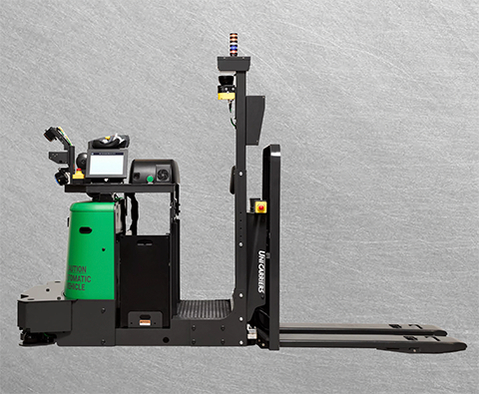

- Vecna Autonomous Pallet Stackers: Autonomous pallet trucks can assist with long-distance pallet hauls and improve put-way efficiency for lift operators. With advanced pallet handling, flexible configurations, dynamic route planning, LPN scanning, task interleaving, and more, Vecna pallet trucks drive efficiency and reduce non-value added travel by 50%.

- Phantom Auto Remotely Operated Forklifts: In July 2021, Kenco became the first North American 3PL to partner with Phantom Auto to utilize its remotely operated forklifts to service customers. Using Phantom Auto’s technology, a warehouse forklift can be operated remotely from anywhere in the world with online connectivity. Operators sit at a console outfitted with a steering wheel and pedals and skillfully operate the vehicles. Phantom Auto’s technology removes geographical restrictions to hiring, thus broadening the labor pool. Additionally, Phantom provides an accessibility aspect by expanding MHE operator jobs to individuals with mobility issues that might have otherwise been unable to operate machinery in-house.

- AutoStore Robotic Shuttles: Kenco is also rolling out AutoStore’s Robotics Shuttle system, an automated storage and retrieval system that packs goods at a high density and uses robots to retrieve them. The system not only saves space with high-density storage, but its automation eliminates the need for the majority of handling equipment, freeing up more space and cutting costs. In our distribution center where AutoStore’s system is deployed, we expect to see $9 million in savings over a five-year period.

- Locus Robotics: Locus Robotics provide efficient and powerful autonomous mobile robotic solutions designed for warehouse fulfillment and increase picking productivity. With Locus, people are kept in the picking aisles as the robots travel back and forth to the packing station, increasing productivity four-fold—from 30 lines per hour to 120 lines per hour at peak—in one eCommerce facility.

- Robopac USA Stretch Wrappers: Automatic stretch wrapping machines provide consistency, speed, and full automation to product packaging. In high-volume facilities, Robopac automatic stretch film wrap machines streamline packaging processes to deliver securely wrapped goods to their destinations damage-free. This technology can reduce product damage that occurs during transport by 40% and reduce film cost by as much as 55%.

- Kenco FleetCloud™ Telematics Solution: MHE fleet operators require strong backend tools to optimize their equipment and overall operations. Kenco’s proprietary FleetCloud™ solution is one of the most powerful telematic devices in the industry today. FleetCloud’s brand-agnostic technology automates material handling equipment service processes and monitors equipment performance to drive efficiency, safety, and compliance. The solution can drive ROI, extend equipment’s lifespan, and drastically reduce costs associated with avoidable damages, battery life, and equipment performance by tracking the efficiency of assets throughout their entire lifecycle.

Key Takeaways:

Shortages in MHE and operators continue to plague warehouses across the country. Luckily, there’s no shortage of innovation meeting the resulting challenges head-on. Visit our comprehensive MHE Fleet Services page to learn more about innovative MHE technologies or speak with a professional today.