Kenco Sustainability Report 2025

Kenco’s 2025 Sustainability Report reflects the company’s continued commitment to supply chain sustainability, environmental stewardship, and …

“In the logistics industry, experience is the new differentiator and the opening of the Kenco Innovation Lab facility will only heighten our industry experience and insight. Our work in the Innovation Lab has already brought value to our customers. This lab facility will provide a formal space to review, research and promote technology to only further assist in our goal to provide the greatest insight to our customers.”

— Kristi Montgomery, Vice President of Innovation at Kenco

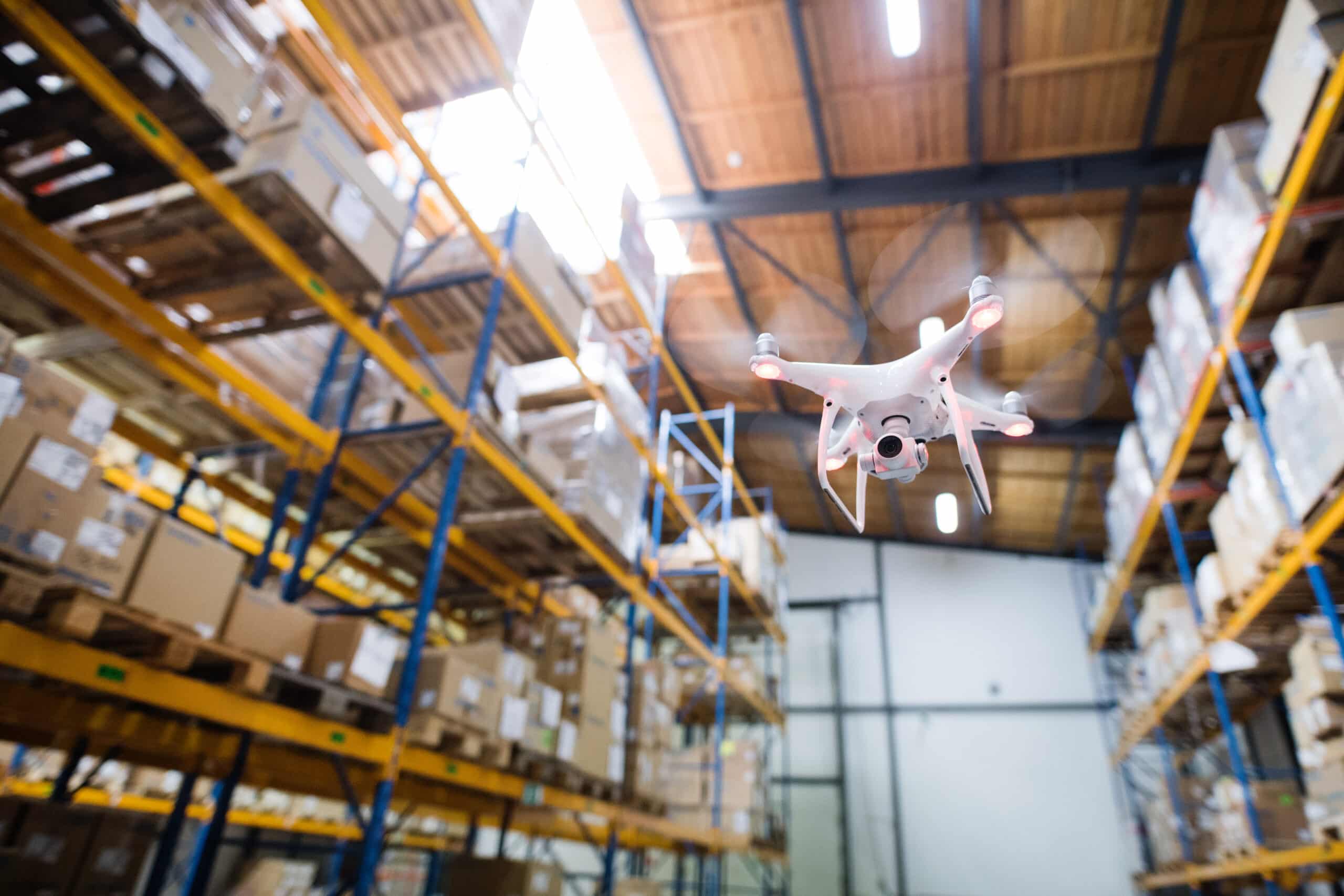

Kenco’s Innovation Lab is our commitment to continuous improvement for our customers. A 10,000 square foot warehouse based in Chattanooga, TN, the Innovation Lab is dedicated to researching, testing, and vetting new supply chain technologies and ideas in a controlled setting.

Savings Identified Within First Year of Our 2019 Expansion

With thoughtful adoption of technology, Kenco is driving new efficiencies and value for our customers.

Safety is an innate part of Kenco’s operations. We take every opportunity to test and implement new technologies to keep our associates safe on the job. For our drivers, vehicles are equipped with SmartDrive technology to detect and prevent potential collisions. Associates on the warehouse floor are given high-performance PPE and exoskeletons to prevent injury.

Our approach to problem solving starts by working directly with the customers and users closest to the challenge at hand. Through collaboration, experimentation, and iteration, we develop purposeful solutions proven to add value to your supply chain.

Reports and Insights

Kenco’s 2025 Sustainability Report reflects the company’s continued commitment to supply chain sustainability, environmental stewardship, and …

News

Executive honored for her leadership, innovation, and contributions to advancing the global supply chain profession CHATTANOOGA, Tenn. — …

News

The Digital Transformation award recognizes Kenco’s partnership on Whirlpool’s Enterprise WMS Project (more…)